3D Printers: Difference between revisions

mNo edit summary |

|||

| Line 77: | Line 77: | ||

''It is important that you select PLA, since that is what we selected when generating the G-Code.'' | ''It is important that you select PLA, since that is what we selected when generating the G-Code.'' | ||

Use the menu to tell the Prusa that you want to load PLA filament into it. | |||

[[File:Prusa_intro_load_filament_screens.png]] | |||

''Below here is still being rewritten'' | ''Below here is still being rewritten'' | ||

Revision as of 05:02, 3 March 2024

Quick Start Instructions

These instructions are currently in the process of being re-written and updated.

PrusaSlicer

Hacklab Toronto has consensus around using PrusaSlicer for new users. [Download and Install PrusaSlicer]

Your First Print

If you are new to 3D printing we ask that you use HackLab's Pusa Mini printers for your first prints, with PrusaSlicer as the slicer. These are our most reliable printers, and simplest to use.

The Toolchain

These instructions will take you from an STL file to a printed object. An STL describes the idealized 3D object you want to produce. We won't cover producing the STL file. For the purpose of following this tutorial you can use this STL file, which describes a small storage bin.

This tutorial will cover how to use PrusaSlicer to convert an STL into GCode, and how to use this GCode to print on the PrusaMinis.

Installing and setting up PrusaSlicer

You will need to install it to be able to convert your STL into G-code. PrusaSlicer runs on your computer, not on the printer itself. Download it from [1] and install it.

After installation you will be presented with several setup pages. To set up PrusaSlicer to work with the HackLab PrusaMinis (and avoid the risk of selecting the wrong printer type be accident) do the following:

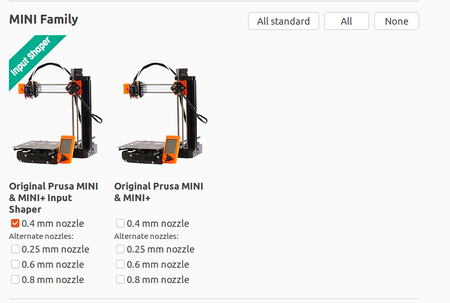

- Under the "Prusa FFF" page: Scroll down to "MINI Family" and select "0.4mm nozzle" under "Original Prusa MINI & MINI+ Input Shaper". Make sure all other printers are not selected.

- Skip through the "Prusa MSLA", "Other Vendors" and "Custom Printer" pages.

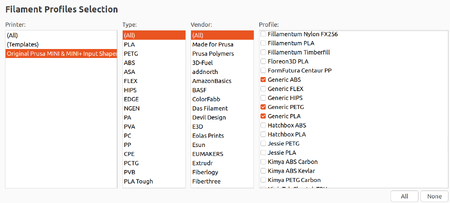

- Under "Filaments" page: make sure Generic ABS, PLA and PETG are selected. Make sure other filaments are de-selected.

- Skip though "Updates", "Downloads", "Reload from disc".

- Under the "View mode" page select "Expert mode".

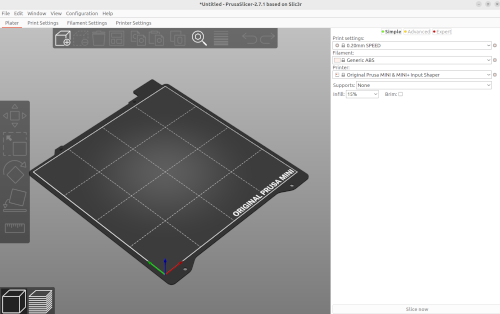

You should now be presented with PrusaSlicer showing a blank build plate.

Slicing with PrusaSlicer

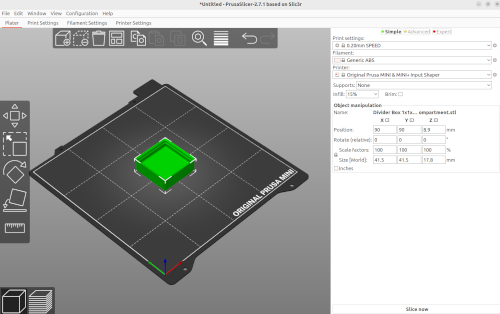

You should have PrusaSlicer open showing a blank build plate:

Import you STL (note: do not "open" a project with Ctrl-O, you are "importing" an STL with Ctrl-I).

The build plate should show the object you just imported - check that it looks like the thing you intend to print!

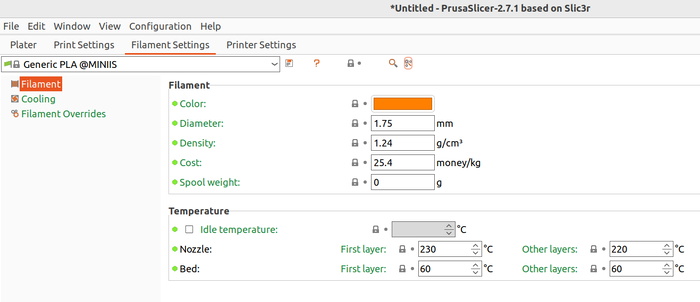

For your first print, you will be printing using PLA. Go to the "Filament Settings" tab and select "Generic PLA @MINIIS" from the dropdown menu. This step is very important. If you do not have the correct filament type selected, the printer will use the wrong temperature and may not melt the filament.

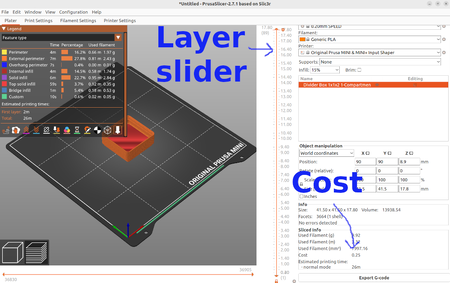

Return to the "Plater" tab and select "Slice Now" (it's in the lower right). Your display will change to show the object that will be printed, rather than the idealised 3D model that you have imported. The bar at the right hand side can be dragged up and down to change which layers are shown. This can be useful to visualise how the interior of your model will be infilled. Look at the lower right where there is a "Sliced info" panel and a field "Cost". In my example it reads "0.25", so this is costing 25c of filament. Please put the cost of your print in the donation jar.

Click on "Export G-code" and save the file as a .bgcode. There may be a warning about only some printers supporting this. Click "OK" - our Prusas support this.

Printing the G-Code

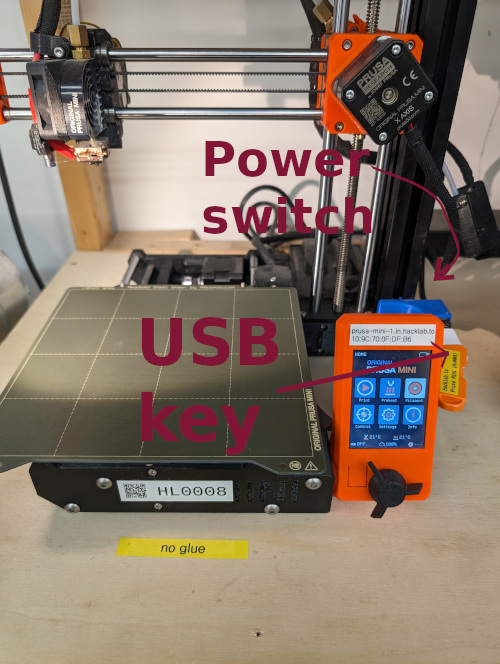

Take the USB key from the printer and connect it to your machine, copy the .bgcode file you just saved to the key, and then return it to the printer. Switch the printer on (the power switch is near the base on the right hand side.)

Note: you may get an error message on the printer about "Firmware file missing in the USB flash". This seems to be solvable by removing the USB key, switching the printer on, and then inserting the USB key after the printer is already switched on. We are trying to resolve the underlying reason for this.

Next you must select and load filament. Hacklab has a stock of filament on a shelf and in some yellow buckets near the printers.

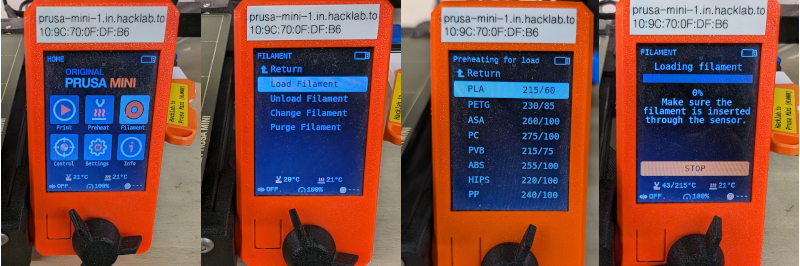

It is important that you select PLA, since that is what we selected when generating the G-Code.

Use the menu to tell the Prusa that you want to load PLA filament into it.

Below here is still being rewritten

Prusa Mini

Hacklab's main printers are the Prusa Mini.

Prusa Mini

- Generate Gcode from an STL using PrusaSlicer

- Copy your Gcode to the USB key attached to the printer.

- Click Print

- When finished, allow the bed to cool, and then wipe clean with small amount of isopropyl alcohol on clean paper towel.

DO NOT LEAVE MACHINES UNATTENDED

Please do run 3d printers with being present in the Lab. If a printer fails it could result in cooked filament / extruders, damaged mechanical components, or fires.

Explore Further

Firmware and Configuration

- Wiki doesn't like weird file types so check out our Github

Machines at Hacklab

| Machine | Status | Additional notes |

|---|---|---|

| File:Prusa Mini 1.jpg 3D_Printers/Prusa Mini 1 |

|

|

| File:Prusa Mini 2.jpg 3D_Printers/Prusa Mini 2 |

|

|

3D_Printers/Ender_5_plus |

|

|

| File:Ender 3 1.jpg 3D_Printers/Ender_3_1 |

3D Printers/Ender 3 1 | |

| File:Ender 3 2.jpg 3D_Printers/Ender_3_2 |

3D Printers/Ender 3 2 | |

| File:CR10 1.jpg 3D_Printers/CR10_1 |

|

|

| File:CR10 2.jpg 3D_Printers/CR10_2 |

|

|

3D_Printers/FlashForge Creator Pro |

|

See individual printer pages for details and maintenance logs.

Physical Problems

- Print not sticking to bed

- Check bed levelness (Prusa's probe this automatically)

- Check print bed distance to print head (Live Z height adjust)

- Extruder no longer extruding filament

- Check filament feeder for ground plastic preventing extrusion

- Check gcode generator settings to ensure proper filament properties selected (diameter, density)

- Inspect hot-end for plugs by manual extrusion at temperature

- Check filament feeder spring pressure (WARNING: DO NOT ADJUST THIS UNLESS YOU KNOW WHAT YOU ARE DOING, THIS IS THE LAST STEP)

- Extrusion is discontinuous

- Check filament feeder for ground plastic preventing full continuous extrusion