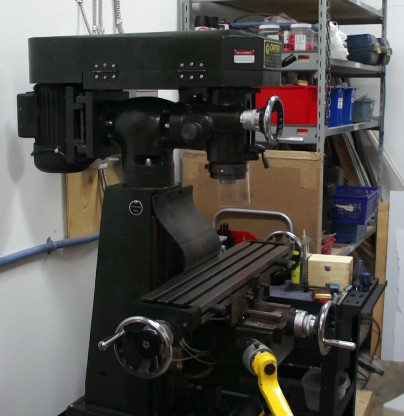

Milling Machine

Hacklab has acquired a milling machine as of Aug. 29 2015!

Some things about it:

- Model: Craftex CT054

- Busy Bee manual

- Similar to Grizzly G3102 - Manual

- 2HP motor

- R8 spindle accepts industry standard tool holders

- Speed is adjusted with belts: 240-2760 RPM

- Longitudinal Table Travel (X-Axis): 15-5/8"

- Cross Table Travel (Y-Axis): 6"

- Vertical Table Travel (Z-Axis): 14"

- Spindle travel (Z-Axis 2): 2-1/2"

- Max Distance Spindle to Column (Y): 5-1/2"

- Max Distance Spindle to Table (Z): 12-1/2"

- Table size: 26-2/5" x 6-1/4"

- T-Nut thread: 3/8-16

- Head Tilt: ±45°

- Turret Swivel: ±45°

- DRO on X, Y, and soon to be on Z (knee)

- Currently no CNC or power feed functions but we're looking into adding this

- A set of tools and accessories are available to use with the machine or you can bring your own

- Video of the installation: https://youtu.be/tWJ8bkSZlN0

Usage & Safety

The milling machine is both a precision machine and also powerful enough to seriously hurt you. It needs to be treated with the same respect you would give any precision tool. All members are welcome to use the machine after being shown how to use it properly.

- Only trained members may use this machine.

- Tie back long hair, remove long sleeved shirts and jewelry.

- Eye protection must be worn when machine is running.

- Check all tooling and machine for damage before using.

- Sweep / vacuum up chips and leave the machine clean.

- No unconventional / unsafe use.

- Usage on non-metals requires your own tools.

- No hammering on the machine table. It is high precision!

- You break it, you buy it!

You MUST be trained before using this machine. Please consult a member who knows what they are doing. You can help a guest with a job but guests are not permitted to use the machine themselves.

Note that knowing how to use a milling machine is not sufficient - You must be shown by a trained member the intricacies of our machine.

Feeds and Speeds / Feed Direction

- Learn about feeds and speeds for the cutter diameter and material you are using. Too fast or slow RPM can damage cutters and make it harder to work.

- Learn about cutting direction (climb vs. conventional cutting) and use the correct feed direction. Climb cutting takes more effort on the handwheels!

- There is a chart on the mill cart for calculating the maximum RPM for a given tool bit size and material. The chart was generated using this calculator (source code).

Tips and Advice

- Non-metals are okay, but you should use your own tools and be extra careful if you don't know how the material will behave.

- The fine adjust handwheel on the quill is not as accurate as the knee for up/down motion. Lock the quill before milling and use the knee to plunge into the material or to set the height of your cut.

- To change tools in the same collet don't unscrew the drawbar more than a few turns. Tap with a rubber mallet to loosen the collet and change the tool. Push the tool in as far as possible.

- Don't use end mills in the drill chuck! The accuracy will be much lower and you will risk breaking the tool.

- Four-flute end mills cannot plunge as fast as two-flute type. Go easy on it.

- Clean out the spindle before mounting the collet or drill chuck to reduce the runout on the tool.

- Do not mill structural-grade steel. It contains impurities which can damage tools.

- Plan your moves to avoid ruining your part or cutting into the table or the vice. These are expensive for you to replace!

- Pass the material with approx. 1/3 or 2/3 of the tool end cutting into fresh material. Do not centre the tool on the edge of fresh material.

- You can plunge up to 1/2 the cutter diameter per pass. The end mill is not a drill bit!

- Take the cutter away from the material before turning off the motor.

- Do not use oil on aluminum except for drilling or tapping.

Accessories

Digital Readout

The mill is fitted with a TDS-3i DRO. The Z axis scale is not installed on the knee yet, needs brackets made and power switch box relocated.

Supplies

- Busy Bee Tools: http://www.busybeetools.com

- Accusize: http://www.accusizetools.ca/upfile/2014-2015.pdf

- KBC Tools: http://www.kbctools.ca/

Wishlist/TODO

- Lubricate spindle (figure out how and what kind of oil/grease it needs and how to do it first)

- Lubricate anything else not fed by the one-shot oiler: leadscrew nuts, etc.

- Install X-axis DRO scale cover

- Install knee (Z-axis) DRO scale

- Make belt cover close completely instead of hanging up on hinge and motor

- Add metering valves to one-shot oiler manifold to prevent oil going all over the place instead of the ways

- Manifold has 1/8-NPT thread, adapters to 5/32" (~4mm) nylon tube

- Option 1 (McMaster): 1/8 NPT male to 1/8 NPT male + female-female coupler + existing NPT-quick-connect adapter

- Metering Valve for Central Lubrication Pump https://www.mcmaster.com/#2293K13

- High-Pressure Brass Pipe Fitting https://www.mcmaster.com/#50785K91

- Option 2 (Bijur): 1/8 NPT male to 5/32 (4mm) tube + compression nut + compression sleeve + tube insert

- FRA-1 1/8 NPT to 5/16-24 thread, 5/32" OD tube meter unit B3216

- 5/32 tube 5/16-24 thread compression nut B1095

- 5/32 nylon tube single-sided sleeve B8272

- 5/32 tube insert steel 19268 for 5/32 .025 wall nylon tube

- Need to select valve flow ratings to balance amount of oil going to different dovetails, machining forums seem to use a mix of #0 and #1 or all #1 valves

- Problems:

- Valves can get clogged with wrong type of oil, dirt, etc.

- Valves are impossible to clean and need to be replaced if that happens

- Need to unplug tubes to test if valves still flowing. Would a pressure gauge on the manifold show a difference when a valve stops flowing?

- Expensive! Is squirting oil everywhere cheaper, and good enough to keep the machine lubricated?

- Misha's Test:

- Using PU-156F-7 polyurethane tubing (95A durometer), already have a large amount

- Table covers to prevent dropping things on table

- Cheapo caliper-style DRO for quill travel

- X-axis Power feed