HackCNC: Difference between revisions

(Add links to fusion settings files) |

|||

| (One intermediate revision by one other user not shown) | |||

| Line 44: | Line 44: | ||

Idea! -->3D model -->Does it (and the clamps needed to make sure it stays still while machining) fit in the machining box (xyz)? -->Availability/cost of raw material and cutting tools -->CAM/G-code generation -->Double-check that your depth of cut, feeds, and speeds are appropriate -->Cutting simulation to make sure the machine does not crash the cutter into something it should not cut -->Cut raw material to size (on bandsaw or other device) and where applicable ”square” corners -->Attach cutter and clamp squared raw material -->Put on your safety glasses, double check you don’t have any loose hair, clothes, jewelry that can get caught in the machine -->Turn on HackCNC power and load program in linuxcnc -->Make sure you and the HackCNC agree where 0 is for the xyz axis! -->Run the first pass in the air above the z axis with your hand on the e-stop and verify spindle coolant flow -->Cut your parts! -->Lather/rinse/repeat as necessary with other cutters until we acquire an automatic tool changer | Idea! -->3D model -->Does it (and the clamps needed to make sure it stays still while machining) fit in the machining box (xyz)? -->Availability/cost of raw material and cutting tools -->CAM/G-code generation -->Double-check that your depth of cut, feeds, and speeds are appropriate -->Cutting simulation to make sure the machine does not crash the cutter into something it should not cut -->Cut raw material to size (on bandsaw or other device) and where applicable ”square” corners -->Attach cutter and clamp squared raw material -->Put on your safety glasses, double check you don’t have any loose hair, clothes, jewelry that can get caught in the machine -->Turn on HackCNC power and load program in linuxcnc -->Make sure you and the HackCNC agree where 0 is for the xyz axis! -->Run the first pass in the air above the z axis with your hand on the e-stop and verify spindle coolant flow -->Cut your parts! -->Lather/rinse/repeat as necessary with other cutters until we acquire an automatic tool changer | ||

== PCB Workflow == | |||

Check [https://docs.google.com/document/d/1JE3ZdaMEde4q_g6oxhJ-d6-frnd0xzpPRKbd6fkVK28/edit?usp=sharing link to google doc] | |||

== Fusion 360 settings == | == Fusion 360 settings == | ||

These files configure Fusion CAM for the machine. You might have to go into preferences and enable | These files configure Fusion CAM for the machine. You might have to go into preferences and enable Cloud Libraries in General -> Manufacture and Machine Configuration under Preview Features. | ||

To use the files, upload them into the Asset project on the data panel. | To use the files, upload them into the Asset project on the data panel. | ||

Latest revision as of 15:28, 7 March 2020

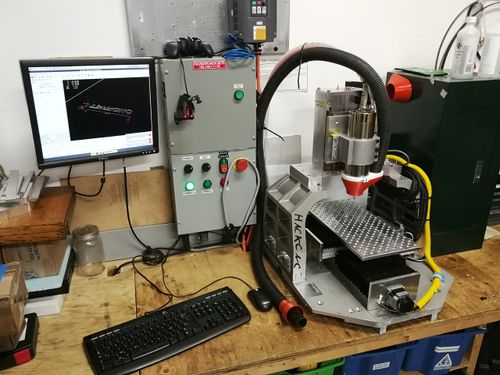

HackCNC is a light-duty CNC mill built around a DNA sequencer

Some things about it:

- 2.2kW (3HP) spindle

- ER20 tool holder

- Variable spindle speed 0-24,000 RPM

- X travel: 126mm

- Y travel: 309mm

- Z travel: 97mm

- The spindle motor can be manually moved up/down to accommodate larger/smaller work

- Table size: 8" x 16" fixture plate 0.4" thick acting as the table

- Table hole pattern: 0.5" x 0.5" checker-board pattern with 3/8"-16 threaded holes (fits mill clamping kit studs)

- Dust collection shroud around spindle with an adapter to connect shop vac

Usage & Safety

The HackCNC is both a precision machine and also powerful enough to seriously hurt you. It needs to be treated with the same respect you would give any precision tool. All members are welcome to use the machine after being shown how to use it properly.

- Only trained members may use this machine.

- Tie back long hair, remove long sleeved shirts and jewelry.

- Eye protection must be worn when machine is running.

- Check all tooling and machine for damage before using.

- Sweep / vacuum up chips and leave the machine clean.

- No unconventional / unsafe use.

- No hammering on the machine table. It is high precision!

- You break it, you buy it!

You MUST be trained before using this machine. Please consult a member who knows what they are doing. You can help a guest with a job but guests are not permitted to use the machine themselves.

Note that knowing how to use a CNC milling machine is not sufficient - You must be shown by a trained member the intricacies of our machine.

Feeds and Speeds / Feed Direction

- Learn about feeds and speeds for the cutter diameter and material you are using. Too fast or slow RPM can damage cutters and make it harder to work.

- Learn about cutting direction (climb vs. conventional cutting) and use the correct feed direction. Climb cutting takes more effort on the handwheels!

- There is a chart on the mill cart for calculating the maximum RPM for a given tool bit size and material. The chart was generated using this calculator (source code).

General Workflow

Not sure what you need to know to start?

Idea! -->3D model -->Does it (and the clamps needed to make sure it stays still while machining) fit in the machining box (xyz)? -->Availability/cost of raw material and cutting tools -->CAM/G-code generation -->Double-check that your depth of cut, feeds, and speeds are appropriate -->Cutting simulation to make sure the machine does not crash the cutter into something it should not cut -->Cut raw material to size (on bandsaw or other device) and where applicable ”square” corners -->Attach cutter and clamp squared raw material -->Put on your safety glasses, double check you don’t have any loose hair, clothes, jewelry that can get caught in the machine -->Turn on HackCNC power and load program in linuxcnc -->Make sure you and the HackCNC agree where 0 is for the xyz axis! -->Run the first pass in the air above the z axis with your hand on the e-stop and verify spindle coolant flow -->Cut your parts! -->Lather/rinse/repeat as necessary with other cutters until we acquire an automatic tool changer

PCB Workflow

Check link to google doc

Fusion 360 settings

These files configure Fusion CAM for the machine. You might have to go into preferences and enable Cloud Libraries in General -> Manufacture and Machine Configuration under Preview Features.

To use the files, upload them into the Asset project on the data panel.

- CAM Machine file: https://myhub.autodesk360.com/ue28038b0/shares/public/SH56a43QTfd62c1cd968614b573aa1467047

- CAM Post file: https://myhub.autodesk360.com/ue28038b0/shares/public/SH56a43QTfd62c1cd96899db40293fa6a194

- Example tool libraries:

- Hacklab fridge magnet (aluminum, 1/4 end mill, 1/4 chamfer/engraver): https://a360.co/2Sj9719

- Hacklab coasters (plywood, 1/8 router bit, 1/4 engraving, spot drill): https://a360.co/38jAwWt

- Wood box (purpleheart, 1/4 end mill, 1/2 end mill): https://a360.co/2SiGgtN

Tips and Advice

- See Mill#Tips_and_Advice

Accessories

- A set of imperial ER20 collets: 1/8" through 1/2"

Supplies

- Busy Bee Tools: http://www.busybeetools.com

- Accusize: http://www.accusizetools.ca/upfile/2014-2015.pdf

- KBC Tools: http://www.kbctools.ca/

Wishlist/TODO

- Hook up the Mesa FPGA

- Make use of the encoders on the X and Y steppers for closed loop control

- Mount FPGA board and breakout board

- Add an encoder on Z

- See if step rates can be increased

- Needs lots of wiring: 5+ wires per encoder

- Spindle speed encoder?

- 4th axis

- Automatic tool changer

Component list

- XY table from DNA sequencer (AB 5500xl Genetic Analyzer)

- 2.2kw spindle from ebay

- fill me