Ultimaker 1: Difference between revisions

(→Status: DOWN ... thermocouple problem) |

|||

| Line 32: | Line 32: | ||

!Notes | !Notes | ||

!Entry By | !Entry By | ||

|- | |||

|Sep 20, 2017 | |||

| | |||

* Removed the Nylon piece between the Fan Duct & the metal block to raise the duct opening a bit more. (In the hope that this would work better) | |||

* '''Carefully''' tweek the angle of the heatblock -- to get as much clearance for Fan Duct as I can. | |||

* Clear yet another Head Jam ... then the Thermocouple no longer works! (Head temp. always reads "off".) | |||

** At the Plywood of the Head, the Bowden Clamp is toooo difficult to get to release. (New clamp needed?) | |||

** I also seemed to have the Heater cable too tight to get the Bowden Tube totally out. (Problem from feeding more cable through head?) | |||

** We seem to be having '''far too many''' head jams with this printer. Does the PEEK and/or PTFE Teflon parts the filament goes through need replacement? | |||

** A separate 12V regulator & a PEEK Cooling fan ( https://www.thingiverse.com/thing:383950 ) should be installed for higher temp. printing. | |||

** And if this head needs to be rebuilt, then this ( https://www.thingiverse.com/thing:344113 ) using ABS looks like the best Filament Fan solution. (NO blocking head view/access, NO turning Heatblock, etc..) | |||

|Allen | |||

|- | |||

|Sep 13, 2017 | |||

| | |||

* Replaced filament cooling fan duct w/ https://www.youmagine.com/designs/tapir-shroud-for-ultimaker ... printed using PETG | |||

* Had to '''carefully''' rotate the heat block about 90° to install that. | |||

** Had to feed a bit more wires through wooden printhead to get slack to do that. | |||

* Resorted to using tie-warps to get this on/installed. | |||

** A piece of (nylon) tie-wrap was put between the Metal printer plate & this part, to prevent warping due to heat. | |||

|Allen | |||

|- | |- | ||

|Sep 8, 2017 | |Sep 8, 2017 | ||

| | | | ||

* Replaced the filament cooling fan duct for a 2nd time. (Heatblock burned through it.) | * Replaced the filament cooling fan duct for a 2nd time. (Heatblock burned through it.) | ||

* This '''large''' cooling fan shroud now is '''extremely close''' to the Printbed ... which produces excellent results, but makes it incredibly difficult to catch the loose filament when a print first starts. (Filament trapped next to the printhead causing prints to fail when first started.) | * This '''large''' cooling fan shroud now is '''extremely close''' to the Printbed ... which produces excellent results, but makes it incredibly difficult to catch the loose filament when a print first starts. (Filament trapped next to the printhead causing prints to fail when first started.) | ||

Revision as of 18:28, 22 September 2017

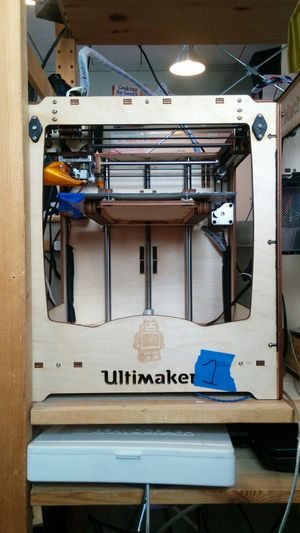

This page documents Ultimaker #1 (Guy). The printer lives on the bottom shelf of the 3D printer tower.

Status

- DOWN ... Thermocouple failure ... DO NOT USE.

- Last known good settings: 220°, 110% flow, print 60mm/s, travel 120mm/s, 0.4 mm nozzle size, 2.85mm filament size.

- Works well using Blue painter’s tape without using the heated bed. (Same setup as Ultimaker 2)

- Cura 15 Settings here

- http://octopi.hacklab.to/

Known Issues and Fixes

- IMPORTANT: OctoPrint will disconnect from Ultimaker 2 if Ultimaker 1 is powered on. If you want to print on both (or will want to eventually), power both on before starting your print on Ultimaker 2

- For better results, wipe the Blue Tape Sheet with Isopropyl Alcohol a few minutes before starting to print.

- If a large solid area is under-extruding then try printing at 220° and 110% Flow. For the PLA/PHA also use 100% fill. (Or figure out the correct retraction settings for that filament.)

- To easily change the filament, rotate this printer 90° -- so that the filament spool points towards the shop door end of the shelving.

Features

- Ultimaker Original with extruder drive upgrade

- 210 x 210 x 205 mm print volume

- 2.85mm filament

- Absolute max temperature: 250 C

- Heated bed for ABS (on second power supply)

- It is managed and accessible from the web GUI: http://octopi.hacklab.to/

Machine Log

| Date | Notes | Entry By |

|---|---|---|

| Sep 20, 2017 |

|

Allen |

| Sep 13, 2017 |

|

Allen |

| Sep 8, 2017 |

|

Allen |

| Jul 3, 2017 |

|

Allen |

| Jun 7, 2017 | Stopped Extruding! ... Something like a C-clip has been lost on the Geared/Knerled shaft. .... For now use a copper wire to hold that shaft in place. The proper part needs to be obtained and installed. | Allen |

| Jun 7, 2017 | Lubricate the Z screw using Superlube Synthetic Grease. | Allen |

| Jun 7, 2017 | Heat bed still "cuts out" and drops to about 28°C after less than an hour of printing. | Allen |

| Jun 7, 2017 | Switched bed heater to the second relay on the breakout board, it verks! | Igor |

| May 30, 2017 |

|

Allen |

| Apr 20, 2017 |

|

Allen |

| Mid-2016 | Nozzle cleaned, Bowden coupler springs replaced. Prints well. Use "ABS juice" to stick ABS prints to bare bed. Prints PLA onto blue tape perfectly as well. | Igor |

| Jan 28, 2016 | THE QUARTERBACK IS TOAST. This printer isn't working. The extruder is spinning but not pushing ABS through. I've done as much troubleshooting as I can without risking screwing stuff up. I've sent a query to the mailing list. | alaina |

| June 8, 2013 | Added tool holder onto side of Ultimaker | Norm |

| May 14, 2013 | Tensioned X/Y belts, switched to white PLA and tested new experimental settings. Readjusted Z bed height, printed stuff. | Norm |

| May 11, 2013 | Rod endcaps removed, threadlock (blue) applied to the M3 screws and setscrews locked into place to prevent loosening. Lubricated Z axis and gantry system. |

Norm |

| May 1, 2013 | Printed and mounted new Z home switch retaining mechanism and calibrated. Z homing much more accurate. Observed further inconsistent extrusion, further investigation found online that the knurled bolt is only useful for the last 3 mm nearest the groove for the delrin clip. Adjusted bolt positioning to move good knurling into position, no further grinding or slipping observed, consistent solid extrusion demonstrated. |

Norm |

| April 30, 2013 | Installed new e-panel composite based build platform. | Geordie |

| April 29, 2013 | Printed and installed new extruder feed gear to reduce backlash during retraction. Observed inconsistent extrusion. Small gaps appearing in extrusion, yet full infill occurring on layers otherwise (ie: not clogged). |

Norm |

| April 27, 2013 | Print quality degraded significantly mid-print. Hot end disassembled, burnt PLA removed from brass tube, and dust/dirt removed from teflon-PEEK interface. Print quality returned to normal. Clogged again, cleaned more thoroughly this time. (Used 1/8" drill bit to handheld scrape out burnt PLA very carefully. PLA diameter changed. |

Norm |

| April 24, 2013 | Squeaking noise observed from Y axis axle. Endcap inset screw noticed to be loose, requires new endcap to be printed, and screw not to be overtightened. |

Norm |

| April 12, 2013 | Bed leveling assist tool printed and built. | Norm |

| April 8, 2013 | Belts retensioned, new bearing endcaps installed to reduce backlash further. | Norm |

| April 6, 2013 | Z axis calibration fixed, Z steps/mm in new profile on Git. X/Y axis backlash observed, infill not meeting walls, delamination observed. |

Norm |

| March 31, 2013 | Z axis calibration issues observed. 25mm Test cube showed ~6.8% Z axis error. |

Norm |