Type A

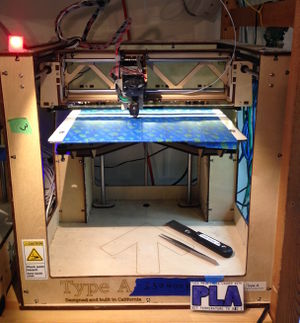

This page documents the Type A Series 1 (2013 plywood model).

Type A lives on the third shelf of the 3D printer tower, next to Ultimaker 2

Status

- DOWN ... Nichrome Wire hotend heater broke

- Loaded with 1.75mm Black PETG

- Cura 15 Settings here

- http://octopi3.hacklab.to/

Known Issues and Fixes

Preliminary CURA 15 settings for MG Chemicals Black PETG

Basic Tab:

- Layer Hight used: 0.15mm (PETG likes more space, so chose this instead of 0.1mm)

- Fill Density used 50% (Just chose something often used with PLA)

- Retraction Enabled

- Z Hop when Retracting: 0.5mm (NO Z Hop used with PLA)

- Print Speed: 30mm/s (Down from 50mm/s for PLA)

- Pringing Temp.: 220°C

- Filament Diameter: whatever a micrometer reads for this reel.

- Flow: 80%

- Nozzle Size: 0.4mm

Advanced Tab:

- Retraction Distance: 3.5mm (Down from 4.5mm for PLA)

- Travel Speed: 250mm/s (Up from 150mm/s for PLA)

Features

- Type A Series 1 (2013 plywood model).

- 254 x 230 x 230 mm print volume

- 1.75mm filament

- .4mm nozzle

- Temperatures readings are lower than Ultimakers (e.g.: 190°C for PLA compared to 210°C on Ultimaker)

- Do NOT run at more than 220°C (which should correspond to a real temp. of aprox. 240°C)

- It is managed and accessible from the web GUI: http://octopi3.hacklab.to/

- Its manual is at http://bit.ly/1NDToMT

Machine Log

| Date | Notes | Entry By |

|---|---|---|

| June 22, 2017 | While trying to fit Hotend Heatsink Cooling Fan, the Nichrome wire broke off right where it goes into the circular ceramic. Now must rebuild using a E3D v6 Head. (As purchased, on the AluHotend heatbreak.) Per instructions on the Internet, that will require changed/custom firmware. | Allen |

| June 17, 2017 |

|

Allen |

| June 13-14, 2017 |

|

Allen |

| May 24, 2017 | 1st attempt to replace Grovemount & Heatbreak ended with a broken part. The needed parts are on order. (Aprox. 30 days from China.) Everything was installed and working briefly before the cracked heatbreak broke. Trying to use the installed Heatsink & Thermal Compound on the Metal Extruder block, instead of a fan on the small metal Grovemount fins. (This rebuild will be simpler if a 2nd fan is not needed.) | Allen |

| April 28, 2017 | Un-Jammed the filament in the print-head. (Jammed in the black quickmount part?) Can push the filament through by hand. (Almost breaking filament using that much force.) But will *not* extrude properly. So something is not moving freely in the quickmount head assembly. | Allen |

| March 28, 2017 | Tried to print, but machine is under-extruding like crazy. The first layer did not lay down, the filament came out like small blobs instead of a constant stream, even at 115% flowrate. I will order a new brass head and teflon tube from china. | ran0 |

| February 18, 2017 | as per @Myles: OctoPi3 is working if you need to use a 3D printer. | MikeP |

| January 2017 | Attempted cleaning nozzle, printer still under-extruding | ran0 |

| January 28 2016 | The X (and to a lesser degree the Y) axis are skipping and it ends up offset. Tightened the belts. All good. | alaina |

| January 1 2016 | Print head not extruding. Mechanics and octopi commands seem to be working fine, but filament does not extrude from print head. Also, the Z axis is off a little, and home is slightly too close to the print head. Easily adjusted by hand. | emmy (saskeah) |

| January 2 2016 | On Igor's advice, I tried pushing through some filament (with the hot end at 185C), and it came through just fine. The pinch wheel needs to be cleaned before using, using the compressed air and little metal brushes by the soldering station. On my to do list (hopefully before end of Tuesday) is to clean out the print head using Igor's "cold push" method, clean the pinch wheel, adjust the Z axis, and re-tape the bed, then print a calibration object to make sure all is good. Also, if anyone else does all of this and wants to print - just a note that the 1.75 inch filament is *super* brittle, so be careful! | emmy (saskeah) |

| January 2 2016 | Cold push clean out of extruder head done, extruder doesn't seem to be blocked. Next step is to clean out the pinch wheel, which is on my to-do before Tuesday, unless someone else feels like taking that on. | emmy (saskeah) |

| January 3 2016 | Pinch wheel cleaned with compressed air. Bed re-taped and cleaned with isopropyl alcohol. Cold push clean of extruder head repeated for good measure (and during a sticky moment unicycledave took the head apart and removed some extra gunk). Z axis adjusted. Attempted a calibration object, z axis held bed too far from the print head. Attempted again with adjustment, print head was too close and scraped the tape. Good news: printer totally functional. Bad news: Z axis still needs tweaking, and part of the bed needs to be re-taped again. | emmy (saskeah) |

| January 4 2016 | Bed re-taped, z axis double-checked. Type A gets my stamp of approval - good to go! | emmy (saskeah) |

| January 10 2016 | Did a test print that came out perfectly calibrated, but with some relatively minor gaps in extrusion. | emmy (saskeah) |

| January 17 2016 | Tried another test print that came out with more pronounced gaps in extrusion. Tried a calibration cube at 220 C, and it came out well. Downloaded the new version of Cura and used the default presets to print another test cube. The presets are fairly different from the previous version, and the test print came out perfectly. | emmy (saskeah) |