Type A: Difference between revisions

m (→Cura 3 Settings: typo fix) |

(→Status: update for loaded w/ Green iPrint3D PETG) |

||

| Line 9: | Line 9: | ||

* '''LIMITED USE''' ... only print using PETG (2nd Printhead for PLA coming.) | * '''LIMITED USE''' ... only print using PETG (2nd Printhead for PLA coming.) | ||

* The Printhead Heatsink Fan is '''always on''' ... so don't leave this printer powered on for long periods of time without printing. | * The Printhead Heatsink Fan is '''always on''' ... so don't leave this printer powered on for long periods of time without printing. | ||

* Loaded with 1.75mm | * Loaded with 1.75mm Green iPrint3D PETG | ||

* [[3D_Printers#Cura_15|Cura 15 Settings here]] | * [[3D_Printers#Cura_15|Cura 15 Settings here]] | ||

* '''http://octopi3.hacklab.to/'''</onlyinclude> | * '''http://octopi3.hacklab.to/'''</onlyinclude> | ||

Revision as of 23:48, 12 November 2017

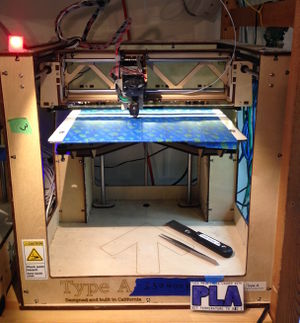

This page documents the Type A Series 1 (2013 plywood model).

Type A lives on the third shelf of the 3D printer tower, next to Ultimaker 2

Status

Zero Stop is out ... turn Z shaft clockwise to get flat/sticking filament

- LIMITED USE ... only print using PETG (2nd Printhead for PLA coming.)

- The Printhead Heatsink Fan is always on ... so don't leave this printer powered on for long periods of time without printing.

- Loaded with 1.75mm Green iPrint3D PETG

- Cura 15 Settings here

- http://octopi3.hacklab.to/

Features

- Type A Series 1 (2013 plywood model).

- 254 x 230 x 230 mm print volume

- 1.75mm filament

- .4mm nozzle

- As the head uses a Teflon insert, do NOT run at more than 240°C (250°C absolute maximum temp.???)

- It is managed and accessible from the web GUI: http://octopi3.hacklab.to/

- Its manual is at http://bit.ly/1NDToMT (our Head Assembly is different.)

Known Issues and Fixes

- Before starting to print, make sure the head heatsink fan is ON. If the connector on the cable came loose, then the filament will jam once that heatsink becomes too hot.

- This Printer has a removable printbed. So before printing, make sure that all 4 screwheads are forward to properly secure the printbed.

IMPORTANT: All PETG filaments are not the same. This printer can only use PETG filaments where the maximum recommended printing temperature is 240°C. (MG Chemicals, Spool3D.ca & iPrint-3D are some sources for that.) Most PETG filaments have a maximum recommended temperature of 260°C to 265°C.

Recommended Filament Settings

CURA 3 settings for iPrint3D Dark Green PETG

Quality

- Draft Quality ==> Layer Height: 0.2mm (Don't use less than this with PETG.)

Infill

- Infill Pattern: Zig Zag

- Infill Overlap Percentage: 50

- Skin Overlap Percentage: 10

The Infill Overlap is extremely high! This value is used to ensure the infill will not separate from the Shell layers.

Material

- Printing Temperature: 240 °C

- Diameter: 1.75 mm

- Flow: 100 %

- Retraction Distance: 0.4 mm

- Retraction Speed: 30 mm/s

Speed (Testing in progress on these settings)

- Print Speed: 25 mm/s

- Infill Speed: 25 mm/s

- Wall Speed 20 mm/s

- Outer Wall Speed: 20 mm/s

- Inner Wall Speed: 25 mm/s

- Travel Speed 240 mm/s

- Initial Layer Speed: 20 mm/s

Travel

- Z Hop When Retracted: SELECTED

- Z Hop Height: 0.5 mm

Support

- Support Pattern: Lines

Cooling

- Enable Print Cooling: UNSELECTED

Special Modes

- Print Sequence: One at a Time

CURA 15 settings for MG Chemicals Black PETG

Basic Tab:

- Layer Height: 0.2mm (Don't use less than this with PETG.)

- Fill Density: 50% or 100% (Just what was used for testing.)

- [... button] Infill overlap (%): 50 (15 for PLA. Very high due to low flow?)

- Retraction Enabled

- [... button] Z Hop when Retracting: 0.5mm (NO Z Hop used with PLA)

- Print Speed: 25mm/s (Down from 60mm/s for PLA)

- Printing Temp.: 240°C

- Filament Diameter: whatever a micrometer reads for this reel.

- Flow: 67%

- Nozzle Size: 0.4mm

Advanced Tab:

- Retraction Speed: 30.0mm/s

- Retraction Distance: 0.30mm

- Travel Speed: 250mm/s (Double what used with PLA)

- Bottom Layer Speed: 20mm/s

- Outer Shell Speed: 20mm/s

- Enable Cooling Fan: UNSELECT this. (not checked)

NOTES: final layer.

- The above settings are a "best compromise", to get good results, without limiting the print speed any more than necessary.

- For best results printing PETG, do not use the Filament Fan. (Print with the Hotend Heatsink Fan only.) When the Filament Fan is used, expect layer separation problems. When printed without using a Filament Fan, PETG has exceptional layer bonding.

- As a filament type, PETG is terrible at things like bridging. This includes you might need just a bit more top surface over infill to get a smooth outer layer.

- As the head moves through spiderweb thin strands between printed parts, PETG filament build-up on the outside of the printhead. Despite this, any print that could be described as a "highly shaped bock of plastic" will probably work. But for prints where the head constantly moves over open air (no plastic under the head), the melted PETG dropping off the outside of the printhead will probably cause that print to fail.

- To print with PETG, start with a clean nozzle; and the 1st layer (inside the Brim) needs to be perfect.

- There are suggestions on the Internet that MG Chemicals PETG is brittle compared to other PETG filaments. So anything that would be "fragile" (too easy to break) when printed with PLA, could also be "fragile" when printed with this PETG.

SPOOL3D Translucent Red PETG (changes to MG Chemicals Black)

- Printing Temp.: 235°C

- Retraction Distance: 0.65mm

NOTES:

- All test printing was done without using the Filament Cooling Fan.

- This filament really oozes ... so a slightly lower Temp. & a much higher Retraction was needed.

- Very little stringing using the above settings ... but POOR Layer Adhesion, and POOR Perimeter to Infill Adhesion.

- Print Temp. too low??? ... need more Infill overlap??? (After testing this filament, the Infill overlap for MG Chem. PETG was drastically increased.)

Cura 3 Settings

To use the below settings, create a Custom FDM printer, then edit the Machine Settings for that printer to contain the following:

Printer Settings

- X (Width): 254 mm

- Y (Depth): 230 mm

- Z (Height): 230 mm

- Build plate shape: Rectangular

- Origin at center: UNSELECTED

- Heated bed: UNSELECTED

- Gcode Flavor: Marlin

Printhead Settings

- X min: 30 mm

- Y min: 30 mm

- X max: 55 mm

- Y max: 60 mm

- Gantry height: 110.0 mm

- Number of Extruders: 1

- Material Diameter: 1.75 mm

- Nozzle size: 0.4 mm

Start Gcode

;Sliced at: {day} {date} {time}

G21 ;metric values

G90 ;absolute positioning

M82 ;set extruder to absolute mode

M107 ;start with the fan off

G28 X0 Y0 ;move X/Y to min endstops

G28 Z0 ;move Z to min endstops

G1 Z15.0 F{travel_speed} ;move the platform down 15mm

G92 E0 ;zero the extruded length

G1 F200 E3 ;extrude 3mm of feed stock

G92 E0 ;zero the extruded length again

G1 F{travel_speed}

M117 Printing...

End Gcode

;End GCode

M104 S0 ;extruder heater off

M140 S0 ;heated bed heater off (if you have it)

G91 ;relative positioning

G1 E-1 F300 ;retract the filament a bit before lifting the nozzle, to release some of the pressure

G1 Z+0.5 E-5 X-20 Y-20 F{travel_speed} ;move Z up a bit and retract filament even more

G28 X0 Y0 ;move X/Y to min endstops, so the head is out of the way

M84 ;steppers off

G90 ;absolute positioning

Machine Log

| Date | Notes | Entry By |

|---|---|---|

| October 31, 2017 |

|

Allen |

| October 12, 2017 |

|

Allen |

| August 30, 2017 |

|

Allen |

| August 29, 2017 |

|

Allen |

| August 21, 2017 |

|

Allen |

| August 10, 2017 |

|

Allen |

| July 13, 2017 | Have a 2nd AluHotend/E3Dv6 hot end for this printer. So multiple easy to change print heads (1 per filament type?) are now possible. | Allen |

| July 4, 2017 |

|

Allen |

| June 22, 2017 | While trying to fit Hotend Heatsink Cooling Fan, the Nichrome wire broke off right where it goes into the circular ceramic. Now must rebuild using a E3D v6 Head. (As purchased, on the AluHotend heatbreak.) Per instructions on the Internet, that will require changed/custom firmware. | Allen |

| June 17, 2017 |

|

Allen |

| June 13-14, 2017 |

|

Allen |

| May 24, 2017 | 1st attempt to replace Grovemount & Heatbreak ended with a broken part. The needed parts are on order. (Aprox. 30 days from China.) Everything was installed and working briefly before the cracked heatbreak broke. Trying to use the installed Heatsink & Thermal Compound on the Metal Extruder block, instead of a fan on the small metal Grovemount fins. (This rebuild will be simpler if a 2nd fan is not needed.) | Allen |

| April 28, 2017 | Un-Jammed the filament in the print-head. (Jammed in the black quickmount part?) Can push the filament through by hand. (Almost breaking filament using that much force.) But will *not* extrude properly. So something is not moving freely in the quickmount head assembly. | Allen |

| March 28, 2017 | Tried to print, but machine is under-extruding like crazy. The first layer did not lay down, the filament came out like small blobs instead of a constant stream, even at 115% flowrate. I will order a new brass head and teflon tube from china. | ran0 |

| February 18, 2017 | as per @Myles: OctoPi3 is working if you need to use a 3D printer. | MikeP |

| January 2017 | Attempted cleaning nozzle, printer still under-extruding | ran0 |

| January 28 2016 | The X (and to a lesser degree the Y) axis are skipping and it ends up offset. Tightened the belts. All good. | alaina |

| January 1 2016 | Print head not extruding. Mechanics and octopi commands seem to be working fine, but filament does not extrude from print head. Also, the Z axis is off a little, and home is slightly too close to the print head. Easily adjusted by hand. | emmy (saskeah) |

| January 2 2016 | On Igor's advice, I tried pushing through some filament (with the hot end at 185C), and it came through just fine. The pinch wheel needs to be cleaned before using, using the compressed air and little metal brushes by the soldering station. On my to do list (hopefully before end of Tuesday) is to clean out the print head using Igor's "cold push" method, clean the pinch wheel, adjust the Z axis, and re-tape the bed, then print a calibration object to make sure all is good. Also, if anyone else does all of this and wants to print - just a note that the 1.75 inch filament is *super* brittle, so be careful! | emmy (saskeah) |

| January 2 2016 | Cold push clean out of extruder head done, extruder doesn't seem to be blocked. Next step is to clean out the pinch wheel, which is on my to-do before Tuesday, unless someone else feels like taking that on. | emmy (saskeah) |

| January 3 2016 | Pinch wheel cleaned with compressed air. Bed re-taped and cleaned with isopropyl alcohol. Cold push clean of extruder head repeated for good measure (and during a sticky moment unicycledave took the head apart and removed some extra gunk). Z axis adjusted. Attempted a calibration object, z axis held bed too far from the print head. Attempted again with adjustment, print head was too close and scraped the tape. Good news: printer totally functional. Bad news: Z axis still needs tweaking, and part of the bed needs to be re-taped again. | emmy (saskeah) |

| January 4 2016 | Bed re-taped, z axis double-checked. Type A gets my stamp of approval - good to go! | emmy (saskeah) |

| January 10 2016 | Did a test print that came out perfectly calibrated, but with some relatively minor gaps in extrusion. | emmy (saskeah) |

| January 17 2016 | Tried another test print that came out with more pronounced gaps in extrusion. Tried a calibration cube at 220 C, and it came out well. Downloaded the new version of Cura and used the default presets to print another test cube. The presets are fairly different from the previous version, and the test print came out perfectly. | emmy (saskeah) |

Parts and Supplies Wish List

- www.aliexpress.com/item/A-Funssor-Silicone-Socks-for-v6-hotend-SILICONE-HEATER-BLOCK-COVER-Heater-Block-Silicone-Insulation-Blue/32823079702.html

- 3pcs (for the 3 Printheads that were purchased), shipped by ePacket (becomes XpressPost in Canada.)

- This is the correct Silicone Sock for the "made in China" E3D clone heat-block that we are using.