Ultimaker 1: Difference between revisions

(Retired Printer) |

|||

| (31 intermediate revisions by 2 users not shown) | |||

| Line 1: | Line 1: | ||

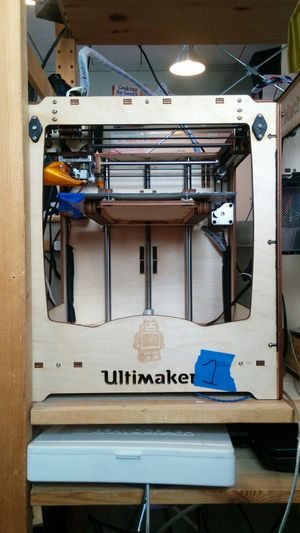

[[File:Ultimaker 1.jpg|thumb|300px|Ultimaker #1, also known as "Guy"]] | [[File:Ultimaker 1.jpg|thumb|300px|Ultimaker #1, also known as "Guy"]] | ||

This page documents Ultimaker #1 (Guy). | This page documents Ultimaker #1 (Guy). | ||

Printer lives on the second shelf of the 3D printer tower, below the [[FlashForge Creator Pro]]. | |||

==Status== | ==Status== | ||

<onlyinclude> | <onlyinclude> | ||

* | * DOWN! ... has a '''serious''' head jam, which will need cold pulls to clear/fix. | ||

* | * '''Last known good settings:''' 220°, 110% flow, print 60mm/s, travel 120mm/s, retraction 4.5mm @ 40mm/s, 0.4 mm nozzle size, 2.85mm filament size. | ||

* | * Silver PLA (from M G Chemicals) | ||

* Works well using Blue painter’s tape '''without''' using the heated bed. (Same setup as Ultimaker 2) | * Works well using Blue painter’s tape '''without''' using the heated bed. (Same setup as Ultimaker 2) | ||

* [[3D_Printers#Cura_15|Cura 15 Settings here]] | * [[3D_Printers#Cura_15|Cura 15 Settings here]] | ||

* '''http://octopi.hacklab.to/'''</onlyinclude> | * '''http://octopi.in.hacklab.to/'''</onlyinclude> | ||

==Known Issues and Fixes== | ==Known Issues and Fixes== | ||

* '''IMPORTANT:''' OctoPrint will '''disconnect from Ultimaker 2''' if Ultimaker 1 is powered on. If you want to print on both (or will want to eventually), power both on before starting your print on Ultimaker 2 | * '''IMPORTANT:''' OctoPrint will '''disconnect from Ultimaker 2''' if Ultimaker 1 is powered on. If you want to print on both (or will want to eventually), power both on before starting your print on Ultimaker 2 | ||

* Recommended CURA '''Retraction Settings:''' 4.5mm at 40mm/s | |||

* For better results, wipe the Blue Tape Sheet with Isopropyl Alcohol a few minutes before starting to print. | * For better results, wipe the Blue Tape Sheet with Isopropyl Alcohol a few minutes before starting to print. | ||

* '''If a large solid area is under-extruding''' then try printing at 220° and 110% Flow | * '''If a large solid area is under-extruding''' then try printing PLA at 220° and 110% Flow. | ||

== Features == | == Features == | ||

| Line 34: | Line 34: | ||

!Notes | !Notes | ||

!Entry By | !Entry By | ||

|- | |||

| June 28, 2020 | |||

| | |||

* This Machine has been retired, replaced by Prusa Mini #1 | |||

| Revident | |||

|- | |||

|September 6, 2018 | |||

| | |||

* "Pipe on back" filament holder replaced by this filament holder on the shelf behind: | |||

https://www.thingiverse.com/thing:3002741 ... used file SpoolRollerL.stl to make this. | |||

* Bed Level was adjusted. | |||

| Allen | |||

|- | |||

|June 22, 2018 | |||

| | |||

* The New (Ultimaker original) Nozzle from Ultimaker 2 was swapped out, to put it on this machine. | |||

* Bed Level was checked, and Zero Stop was adjusted. | |||

| Rana & Hiker ??? | |||

|- | |||

|Oct 10, 2017 | |||

| | |||

* Replace Blue Tape Sheet | |||

* Ajust Zero Stop. (Head '''was''' a bit too high.) | |||

* Print a test pattern to check Bed Level is really good. | |||

|Allen | |||

|- | |||

|Sep 24, 2017 | |||

| | |||

The head was jammed up real good, had to put in some elbow grease to clean it. So apparently a 5 mm long piece of filament had broken off and got stuck in the space where the bowden tube meets the teflon coupler (I think it was in the teflon coupler). So filament was blocked from entering the metal throat. Had to heat up the block, unscrew the nozzle, and poke a thin screwdriver up the throat. Kept poking and removing molten plastic, then finally pushed up on the blocking piece and pushed it through to the bowden tube, which I then disconnected and got that bugger piece out. I must say it was my white whale. | |||

Prints as usual now, which is pretty good. | |||

|rana | |||

|- | |||

|Sep 20, 2017 | |||

| | |||

* Removed the Nylon piece between the Fan Duct & the metal block to raise the duct opening a bit more. (In the hope that this would work better) | |||

* '''Carefully''' tweek the angle of the heatblock -- to get as much clearance for Fan Duct as I can. | |||

* Clear yet another Head Jam ... then the Thermocouple no longer works! (Head temp. always reads "off".) | |||

** At the Plywood of the Head, the Bowden Clamp is toooo difficult to get to release. (New clamp needed?) | |||

** I also seemed to have the Heater cable too tight to get the Bowden Tube totally out. (Problem from feeding more cable through head?) | |||

** We seem to be having '''far too many''' head jams with this printer. Does the PEEK and/or PTFE Teflon parts the filament goes through need replacement? | |||

** A separate 12V regulator & a PEEK Cooling fan ( https://www.thingiverse.com/thing:383950 ) should be installed for higher temp. printing. | |||

** And if this head needs to be rebuilt, then this ( https://www.thingiverse.com/thing:344113 ) using ABS looks like the best Filament Fan solution. (NO blocking head view/access, NO turning Heatblock, etc..) | |||

|Allen | |||

|- | |||

|Sep 13, 2017 | |||

| | |||

* Replaced filament cooling fan duct w/ https://www.youmagine.com/designs/tapir-shroud-for-ultimaker ... printed using PETG | |||

* Had to '''carefully''' rotate the heat block about 90° to install that. | |||

** Had to feed a bit more wires through wooden printhead to get slack to do that. | |||

* Resorted to using tie-warps to get this on/installed. | |||

** A piece of (nylon) tie-wrap was put between the Metal printer plate & this part, to prevent warping due to heat. | |||

|Allen | |||

|- | |||

|Sep 8, 2017 | |||

| | |||

* Replaced the filament cooling fan duct for a 2nd time. (Heatblock burned through it.) | |||

* This '''large''' cooling fan shroud now is '''extremely close''' to the Printbed ... which produces excellent results, but makes it incredibly difficult to catch the loose filament when a print first starts. (Filament trapped next to the printhead causing prints to fail when first started.) | |||

* '''This Filament Fan needs to be replaced with another one of a different design!''' | |||

** Current "best prospect": https://www.youmagine.com/designs/tapir-shroud-for-ultimaker | |||

* X-home switch failed & was ajusted. | |||

** Screws into that micro-switch are '''loose''', so a tiewrap had to be used. | |||

|Allen | |||

|- | |||

|Jul 3, 2017 | |||

| | |||

* Replaced the filament cooling fan duct using the following printed parts: https://www.thingiverse.com/thing:17768 and https://www.thingiverse.com/thing:156119 | |||

** The fan screws were too short for this, so for now the fan is held in place by only 1 screw, until a few more longer M3 screws can be found. | |||

* At the '''very back of the print area''', the fan might still hit the rounded screw heads holding the print bed. Flat head screws have been obtained, so the 4 heatbed screws will be replaced next. | |||

|Allen | |||

|- | |- | ||

| Line 159: | Line 239: | ||

|} | |} | ||

==Parts and Supplies Wish List== | |||

* Hardened Nozzle for printing Carbon Fiber and '''any other''' Filled Filaments (including glow-in-dark). | |||

** A usable Hardened Nozzle from Canada: https://shop3d.ca/products/0-50mm-jet-steel-nozzle-for-olsson-block-rss50 ... $29.38 w/ shipping & tax | |||

*** '''See notes''' about using this nozzle with an UMO here: https://thegr5store.com/store/index.php/um2/rss50.html | |||

** Another possible Hardened Nozzle from Canada: https://spool3d.ca/nozzle-a2-reprap-m6-thread-3mm-filament-ultimaker-2-e3d-olsson-block/ ... $33.38 w/ shipping & tax (No Tracking!) | |||

[[Category:3D Printers]] | [[Category:3D Printers]] | ||

Latest revision as of 02:39, 1 July 2020

This page documents Ultimaker #1 (Guy).

Printer lives on the second shelf of the 3D printer tower, below the FlashForge Creator Pro.

Status

- DOWN! ... has a serious head jam, which will need cold pulls to clear/fix.

- Last known good settings: 220°, 110% flow, print 60mm/s, travel 120mm/s, retraction 4.5mm @ 40mm/s, 0.4 mm nozzle size, 2.85mm filament size.

- Silver PLA (from M G Chemicals)

- Works well using Blue painter’s tape without using the heated bed. (Same setup as Ultimaker 2)

- Cura 15 Settings here

- http://octopi.in.hacklab.to/

Known Issues and Fixes

- IMPORTANT: OctoPrint will disconnect from Ultimaker 2 if Ultimaker 1 is powered on. If you want to print on both (or will want to eventually), power both on before starting your print on Ultimaker 2

- Recommended CURA Retraction Settings: 4.5mm at 40mm/s

- For better results, wipe the Blue Tape Sheet with Isopropyl Alcohol a few minutes before starting to print.

- If a large solid area is under-extruding then try printing PLA at 220° and 110% Flow.

Features

- Ultimaker Original with extruder drive upgrade

- 210 x 210 x 205 mm print volume

- 2.85mm filament

- Absolute max temperature: 250 C

- Heated bed for ABS (on second power supply)

- It is managed and accessible from the web GUI: http://octopi.hacklab.to/

Machine Log

| Date | Notes | Entry By |

|---|---|---|

| June 28, 2020 |

|

Revident |

| September 6, 2018 |

https://www.thingiverse.com/thing:3002741 ... used file SpoolRollerL.stl to make this.

|

Allen |

| June 22, 2018 |

|

Rana & Hiker ??? |

| Oct 10, 2017 |

|

Allen |

| Sep 24, 2017 |

The head was jammed up real good, had to put in some elbow grease to clean it. So apparently a 5 mm long piece of filament had broken off and got stuck in the space where the bowden tube meets the teflon coupler (I think it was in the teflon coupler). So filament was blocked from entering the metal throat. Had to heat up the block, unscrew the nozzle, and poke a thin screwdriver up the throat. Kept poking and removing molten plastic, then finally pushed up on the blocking piece and pushed it through to the bowden tube, which I then disconnected and got that bugger piece out. I must say it was my white whale. Prints as usual now, which is pretty good. |

rana |

| Sep 20, 2017 |

|

Allen |

| Sep 13, 2017 |

|

Allen |

| Sep 8, 2017 |

|

Allen |

| Jul 3, 2017 |

|

Allen |

| Jun 7, 2017 | Stopped Extruding! ... Something like a C-clip has been lost on the Geared/Knerled shaft. .... For now use a copper wire to hold that shaft in place. The proper part needs to be obtained and installed. | Allen |

| Jun 7, 2017 | Lubricate the Z screw using Superlube Synthetic Grease. | Allen |

| Jun 7, 2017 | Heat bed still "cuts out" and drops to about 28°C after less than an hour of printing. | Allen |

| Jun 7, 2017 | Switched bed heater to the second relay on the breakout board, it verks! | Igor |

| May 30, 2017 |

|

Allen |

| Apr 20, 2017 |

|

Allen |

| Mid-2016 | Nozzle cleaned, Bowden coupler springs replaced. Prints well. Use "ABS juice" to stick ABS prints to bare bed. Prints PLA onto blue tape perfectly as well. | Igor |

| Jan 28, 2016 | THE QUARTERBACK IS TOAST. This printer isn't working. The extruder is spinning but not pushing ABS through. I've done as much troubleshooting as I can without risking screwing stuff up. I've sent a query to the mailing list. | alaina |

| June 8, 2013 | Added tool holder onto side of Ultimaker | Norm |

| May 14, 2013 | Tensioned X/Y belts, switched to white PLA and tested new experimental settings. Readjusted Z bed height, printed stuff. | Norm |

| May 11, 2013 | Rod endcaps removed, threadlock (blue) applied to the M3 screws and setscrews locked into place to prevent loosening. Lubricated Z axis and gantry system. |

Norm |

| May 1, 2013 | Printed and mounted new Z home switch retaining mechanism and calibrated. Z homing much more accurate. Observed further inconsistent extrusion, further investigation found online that the knurled bolt is only useful for the last 3 mm nearest the groove for the delrin clip. Adjusted bolt positioning to move good knurling into position, no further grinding or slipping observed, consistent solid extrusion demonstrated. |

Norm |

| April 30, 2013 | Installed new e-panel composite based build platform. | Geordie |

| April 29, 2013 | Printed and installed new extruder feed gear to reduce backlash during retraction. Observed inconsistent extrusion. Small gaps appearing in extrusion, yet full infill occurring on layers otherwise (ie: not clogged). |

Norm |

| April 27, 2013 | Print quality degraded significantly mid-print. Hot end disassembled, burnt PLA removed from brass tube, and dust/dirt removed from teflon-PEEK interface. Print quality returned to normal. Clogged again, cleaned more thoroughly this time. (Used 1/8" drill bit to handheld scrape out burnt PLA very carefully. PLA diameter changed. |

Norm |

| April 24, 2013 | Squeaking noise observed from Y axis axle. Endcap inset screw noticed to be loose, requires new endcap to be printed, and screw not to be overtightened. |

Norm |

| April 12, 2013 | Bed leveling assist tool printed and built. | Norm |

| April 8, 2013 | Belts retensioned, new bearing endcaps installed to reduce backlash further. | Norm |

| April 6, 2013 | Z axis calibration fixed, Z steps/mm in new profile on Git. X/Y axis backlash observed, infill not meeting walls, delamination observed. |

Norm |

| March 31, 2013 | Z axis calibration issues observed. 25mm Test cube showed ~6.8% Z axis error. |

Norm |

Parts and Supplies Wish List

- Hardened Nozzle for printing Carbon Fiber and any other Filled Filaments (including glow-in-dark).

- A usable Hardened Nozzle from Canada: https://shop3d.ca/products/0-50mm-jet-steel-nozzle-for-olsson-block-rss50 ... $29.38 w/ shipping & tax

- See notes about using this nozzle with an UMO here: https://thegr5store.com/store/index.php/um2/rss50.html

- Another possible Hardened Nozzle from Canada: https://spool3d.ca/nozzle-a2-reprap-m6-thread-3mm-filament-ultimaker-2-e3d-olsson-block/ ... $33.38 w/ shipping & tax (No Tracking!)

- A usable Hardened Nozzle from Canada: https://shop3d.ca/products/0-50mm-jet-steel-nozzle-for-olsson-block-rss50 ... $29.38 w/ shipping & tax